Metal vs Plastic Drums for Chemical Storage Solutions

Metal vs plastic drums – the complete breakdown. Regarding chemical storage, selecting an appropriate container is paramount for maintaining product integrity and ensuring safety. Two popular choices for chemical storage are metal drums and poly drums – both offer their benefits and drawbacks, which must be understood before making an informed decision. We will compare metal and poly drums, compare grounding requirements between them, and explain why metal drums are often considered superior options for flammable chemicals storage.

Metal vs Poly Drums: Pros and Cons

Metal and plastic barrels, different types of drums, steel drums.

Metal Drums:

Metallic drums have long been considered an ideal solution for chemical storage due to their durability and resistance against external forces. Metal drums provide excellent protection from impact, puncture, and fire and are resistant to ultraviolet (UV) radiation, making them suitable for outdoor storage.

Metal barrels may present several disadvantages; corrosion is especially susceptible when exposed to certain chemicals or environments that are acidic; over time, rust and degradation could compromise their integrity, leading to leaks or contamination; additionally, metal drums tend to be heavier and more costly compared to their poly counterparts.

Poly Drums:

Plastic poly drums have become increasingly popular over time due to their lightweight nature and resistance to chemical corrosion. HDPE material is inherently resistant to many chemicals and substances used for storage, making this alternative option less expensive than metal ones.

Poly drums do not offer the same level of impact and fire protection as metal ones, making them more prone to punctures, cuts, extreme temperatures, and chemical interaction, which could weaken or permeate its material, potentially endangering its contents.

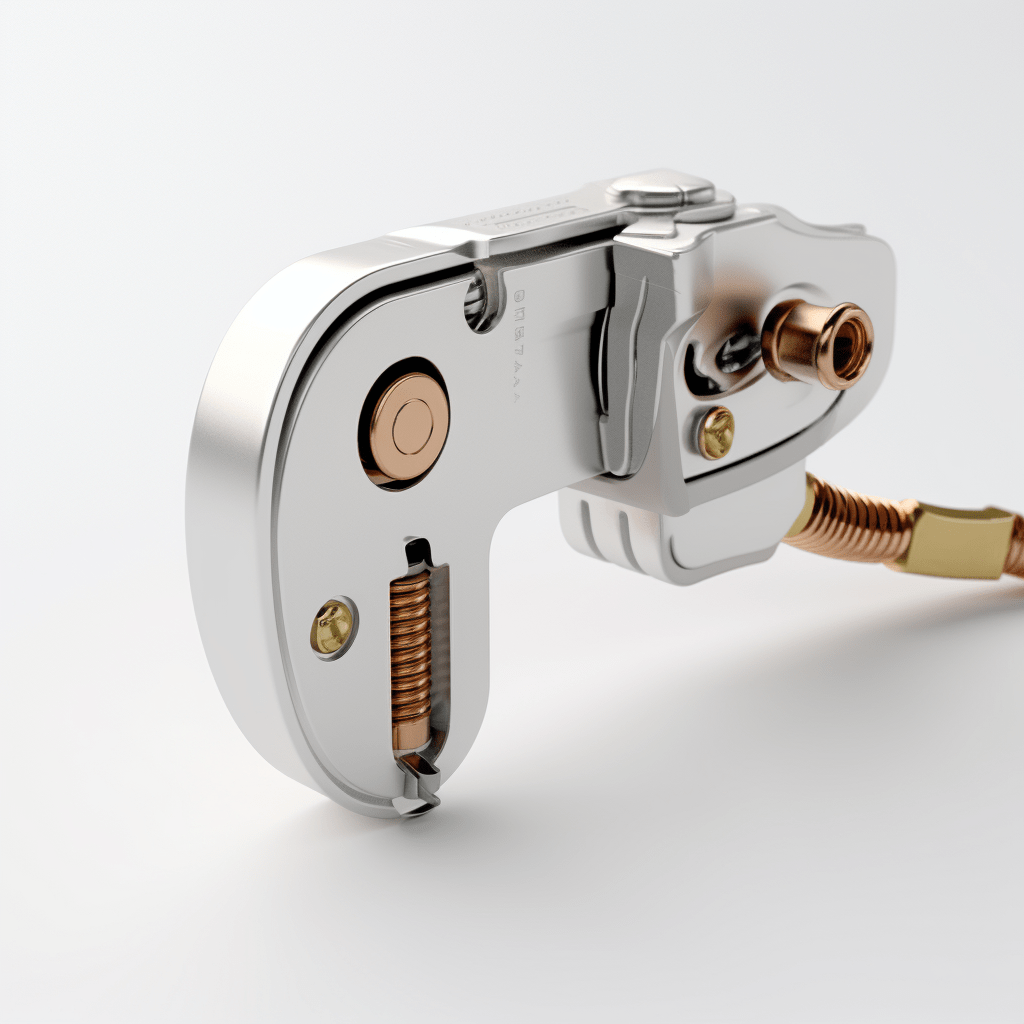

Grounding Requirements:

According to safety regulations, metal drums steel, and poly drums must comply with grounding requirements when storing liquids with flashpoints below 100degF (37.8degC). While bonding non-conductive containers like poly drums may seem unnecessary for this task, static charges still accumulate during liquid movement that could spark fires that ignite flammable vapors, causing dangerous situations.

Employers looking to bond non-metallic containers can achieve proper bonding through fill tubes, grounding wires, or metallic pumps connected to a ground source. Many modern plastic containers also contain embedded ground wires to allow grounding as necessary and increase safety during dispensing and storage operations.

Bonding & Grounding Clamps are Crucial

Metal Drums Are The Superior Choice For Flammable Chemicals:

Metal drums offer distinct advantages when storing flammable chemicals classified as classes 1, 2, or 3, including those classified as classes 1 through 3. Simple Solvents products include class 3 hazmats (200 Proof Ethanol, 190 Proof Ethanol, n-Pentane, n-Heptane, and n-hexane)

Metal vs poly drums: Here are the primary reasons for their superiority:

Fire Resistance: Metal drums offer excellent fire protection than poly drums in terms of fireproofing properties, making them more likely to contain flames and prevent the spread of hazardous materials, lowering risks associated with explosions and injuries.

Impact Protection: Metal drums offer superior impact protection, protecting their contents from accidental damage during transportation, handling, or storage. This feature is essential when handling volatile substances that could become highly reactive over time.

Longevity: Metal drums typically outlive poly drums when maintained and protected against corrosion adequately, providing long-term storage integrity of stored chemicals over an extended period.

Conclusion

Regarding chemical storage (metal vs poly drums), selecting an appropriate container is paramount for maintaining safety and avoiding accidents. While poly drums have benefits, metal drums offer additional protection when dealing with potentially flammable substances. Metal drums provide superior fire resistance, impact protection, and longevity for storing class 1, 2, and 3 volatile chemicals. Ensure your metal and poly drums are properly grounded to protect against static charges and create a safe working environment. By understanding their respective properties and considerations, you can make an informed decision and ensure the secure storage of chemicals at your facility.

Rest assured, all Simple Solvents products ship in metal drums. This ensures the highest quality product accompanied by industry standard safety.